[Mechanically deformed membranes enable fast and selective hydrogen separation, with industrial promise at low energy cost.]

Most of the world’s hydrogen, often touted as a green fuel, is produced alongside carbon dioxide. The challenge is separating the clean from the dirty. Conventional membranes can either sieve molecular with pinpoint precision or let them pass rapidly — but hardly at the same time. It’s a longstanding compromise that has hamstrung efforts to scale up hydrogen purification without incurring substantial energy costs.

Now, researchers at the Institute for Functional Intelligent Materials (I-FIM), National University of Singapore, have proposed a workaround, not by inventing a novel material, but by reimagining the shape of an existing one.

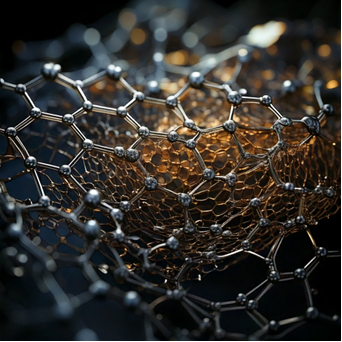

Detailed in a paper published in Nature Nanotechnology on 14 July 2025, Associate Professor Daria Andreeva, Principal Investigator at I-FIM, and her team introduced a crumpled form of graphene oxide (GO) that achieves both high permeability and high selectivity for hydrogen over carbon dioxide. The membranes perform reliably under harsh conditions and could operate at far lower pressures than current industry standards — a boon for energy-efficient decarbonisation technologies.

Eat your pie and still have it warm

With their lamellar structure, featuring neatly stacked nanosheets with narrow interlayer gaps, GO membranes are highly selective and excel in separating a wide range of ions and molecules. It’s also a double-edged feature. GO membranes are typically tightly packed, making it difficult for gas molecules to travel through, especially when the membrane needs to be thick enough to withstand industrial pressure. As a result, permeability, or the ease with which molecules pass through a material, drops and practical deployment stalls.

To crack the selectivity-permeability impasse, Assoc Prof Andreeva thought: what happens when GO sheets are crumpled? Would that make a difference?

Her team layered a flat GO film on a polystyrene substrate that shrinks when heated. As the substrate contracts, it compresses the GO film into a wrinkled structure. The resulting membrane features a multi-domain architecture, with a mix of compact regions and expanded ones. Crucially, these diverse nanostructures govern how gases move about. Narrow regions act as tight molecular filters, allowing smaller hydrogen molecules through while blocking larger carbon dioxide molecules. Expanded regions, on the other hand, help gases enter and travel across the membrane more freely. Working together, these features create two types of transport pathways that work in tandem: one for selectivity, one for permeability.

“When we started, we wondered if it was possible to increase gas throughput in GO membranes without losing their molecular sieving ability,” said Assoc Prof Andreeva. The inspiration came from earlier work on wrinkled gold films, which led them to explore a polymer-based method to induce strain in the membranes — a process that turned out to be both scalable and surprisingly stable. “The biggest challenge was maintaining structural uniformity across large areas,” she added.

To overcome this, the researchers carefully controlled the adhesion between the GO nanosheets and the polystyrene substrate, while fine-tuning the thickness of the deposited layer. These key parameters ensured that the membrane crumpled consistently across the surface.

Their experiments showed that the crumpled membranes achieved hydrogen permeability exceeding 2.1 × 10⁴ barrer — nearly four orders of magnitude higher than their flat counterparts — while maintaining an H₂/CO₂ selectivity of 91, and peaking at 113.5 in mixed-gas conditions. Even under harsh conditions like –20 °C and 96% humidity, the membranes performed without hiccups. Standard polymer membranes would typically perform poorly under such stress, but the crumpled version retained most of its selectivity and permeability. Crucially, it also performed well at just 3 bar of pressure, compared to 15–30 bar often required in industrial hydrogen purification.

Know when to fold ‘em

The ability to decouple permeability and selectivity is a boon for membrane-based separations in applications such as carbon capture, industrial gas processing and fuel cells. In particular, the membranes could produce highly pure hydrogen (99.5%) at low pressures, thus reducing the energy cost of purification — down to an economically competitive rate of US$0.12 per kilogram of CO₂ removed , according to the team’s cost analysis.

“The authors demonstrate mechanochemically engineered crumpled graphene oxide membranes that employ a compartmentalised multidomain architecture to govern gas diffusion pathways,” said Professor Haihui Wang from Tsinghua University, who was not involved in the study. “This architecture has a structurally distinct topology from conventional 2D lamellar systems and enhances gas permeation while retaining molecular selectivity, overcoming the H₂/CO₂ permeability–selectivity trade-off with demonstrated durability and scalability.”

Future work will involve testing these membranes under real-world conditions, where gas streams can include impurities like water vapour and carbon monoxide. The team will also assess the long-term performance of the membranes under fluctuating flow rates and pressures.

Assoc Prof Andreeva envisions that the strategy of strain-engineering membrane morphology would inspire further advances in 2D materials research. “We hope that our method will be developed further and be used for the design of next-generation membranes,” she said.