Furnace room

The furnace room is a dedicated facility to support high temperature equipment such as plasma enhanced chemical vapor depositors (PE-CVD), thermal evaporators, muffle furnaces and convection ovens. Applications range from growing graphene, boron nitride (BN), transition metal dichalcogenides (TMD) to sample annealing, baking and pyrolysis. Each growth chamber is equipped with dedicated programmable mass flow controllers (MFC’s) and pumping system for process specific gas and pressure requirement. In the preliminary stage, the furnace facility will heavily produce candidate materials to be investigated as potential Functional Intelligent Materials (FIM’s). Whereas in the long term, as part of the proposed Materials Robotics Lab (MRL), it will house high throughput growth chambers which are expected to churn out materials with predesigned structures and functionalities, aided by Machine Learning (ML) capabilities.

| List No. | Key Specifications | Picture |

| A | Horizontal furnaces

Two-Zone Split Tube Furnace

|

|

Single-Zone Tube Furnace

|

|

|

| B | Customized PE-CVD

|

|

| C | Vacuum drying oven

|

|

Muffle furnace No 1

|

|

|

Muffle furnace No 2

|

|

|

Convection oven

|

|

|

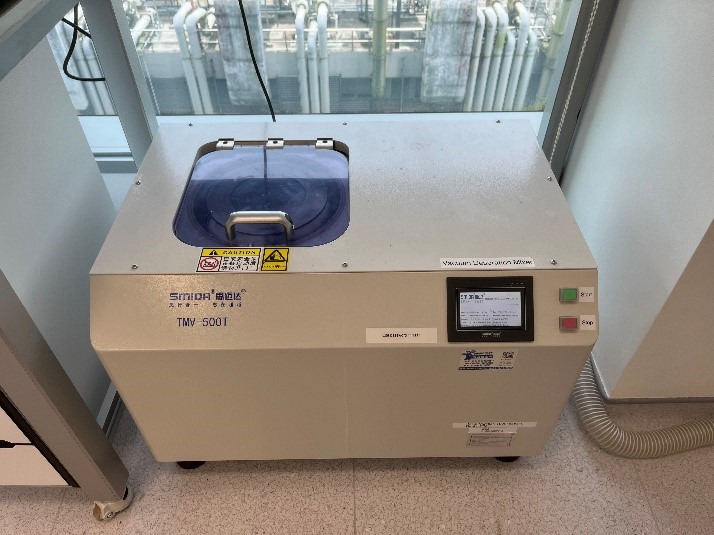

| D. | Vacuum Deaeration Mixer

noncontact mixing mode. |

|