Sample Growth lab and Nano/Fabrication Facility

The grand research plan for I-FIM envisages identifying and fabricating material components for Functional Intelligent Materials (FIM’s). In particular, strong emphasis would be given to develop heterostructured materials with novel interactions at their interface. To this end, the preliminary facility building in I-FIM comprises a) upgrading the existing cleanroom facilities at the Centre for Advanced 2D Materials (CA2DM) and b) setting up new fabrication facilities on the I-FIM premises.

a) Upgrading the existing cleanroom facilities at the Centre for Advanced 2D Materials (CA2DM)

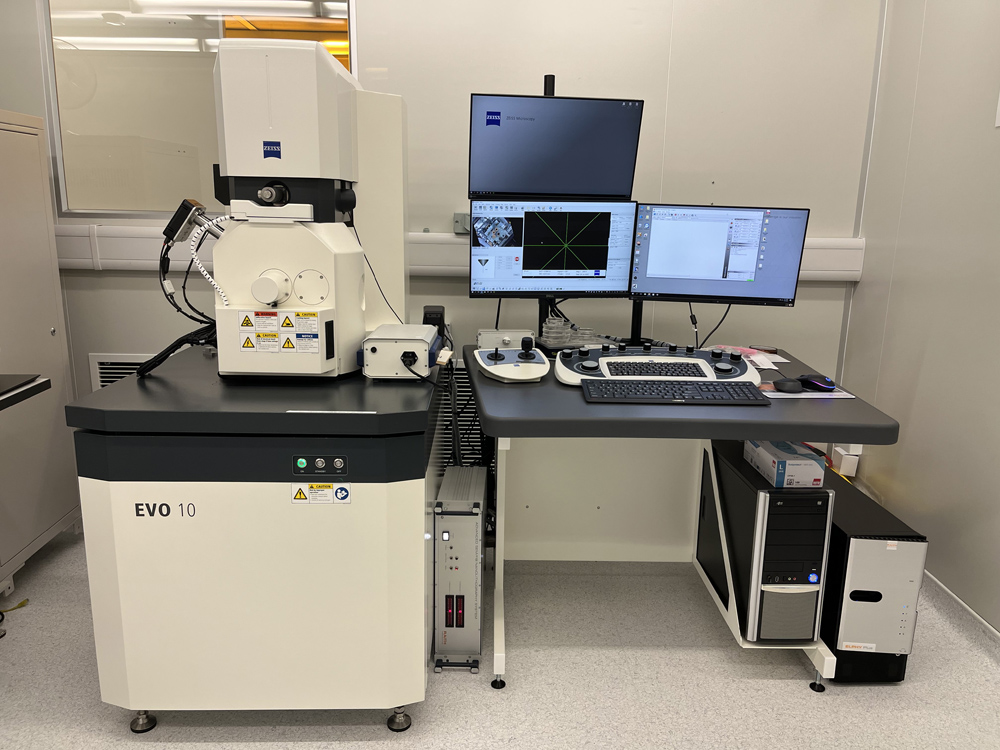

The Zeiss EVO 10 is equipped with LaB6 Electron Emitter, Zeiss SmartEDX and Raith's ELPHY Plus Pattern Generator. At challenging imaging conditions, LaB6 users benefit from up to 10 times more beam brightness, resulting in enhanced image resolution and contrast. The SmartEDX, which is designed to acquire spatially resolved elemental information from the sample surfaces, can obtain its highest throughput at 129 eV energy resolution at typical SEM operating conditions. Raith's ELPHY Plus pattern generator is a high-performance lithography attachment that transforms our Zeiss EVO into a nanofabrication tool. Our machine is designed to pattern smaller device areas, up to a maximum of 2mm x 2mm at a time, in one single write field. In its fully automated exposure sequence, the system can switch between smaller beam currents for higher-resolution nanostructures patterning and high beam currents for large area exposures to minimize the patterning time without sacrificing the pattern resolution at sensitive regions. Its proximity effect correction package NanoPECS can also assist our users to optimize dose distribution for critical parts of their design.

b) Sample Growth Lab

I-FIM recently launched an in-house sample fabrication facility to meet the increasing demand for high quality van der Waals heterostructures and other layered materials. It houses a home-built semi-automatic transfer system comprising of high magnification microscope, precision optics, temperature controller and micro-manipulators for XYZϴ motion, all mounted on a high level of vibration isolation. The combination of such precision elements allows manipulation of 2D materials on other single crystalline structures, even allowing users to control the twisting angle between layers. The current system is used in ambient condition, while preparation is underway to build a 2nd system within an inert glovebox environment to handle air sensitive materials. Such a fabrication facility is expected to improve existing recipes and create innovations for synthesizing, manipulating, and characterizing novel materials. Ultimately, it will contribute to I-FIM’s journey of self-reliance for material production.